Call us 9:00am - 6:00pm

+971 50 673 6705

Monday to Friday

9:00am - 6:00pm

E-mail us

cs@rudra-ventures.com

What is ePTFE?

ePTFE stands for expanded polytetrafluoroethylene, a form of PTFE (Teflon) that has been expanded to create a porous, flexible material. This expansion process gives ePTFE unique properties like high compressibility, flexibility, and chemical resistance.

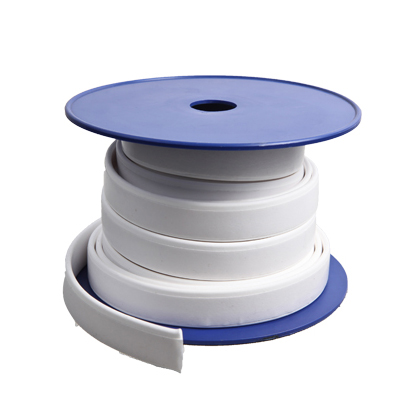

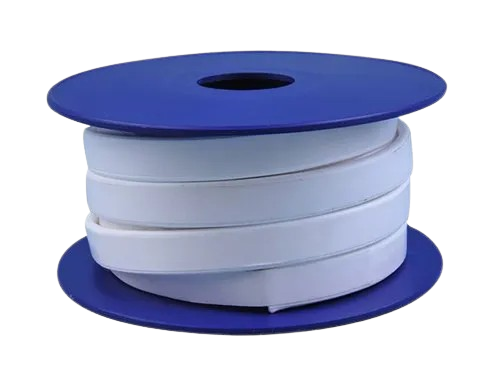

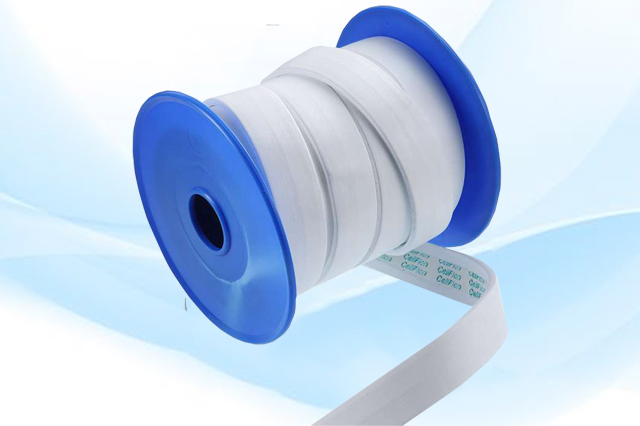

ePTFE tapes

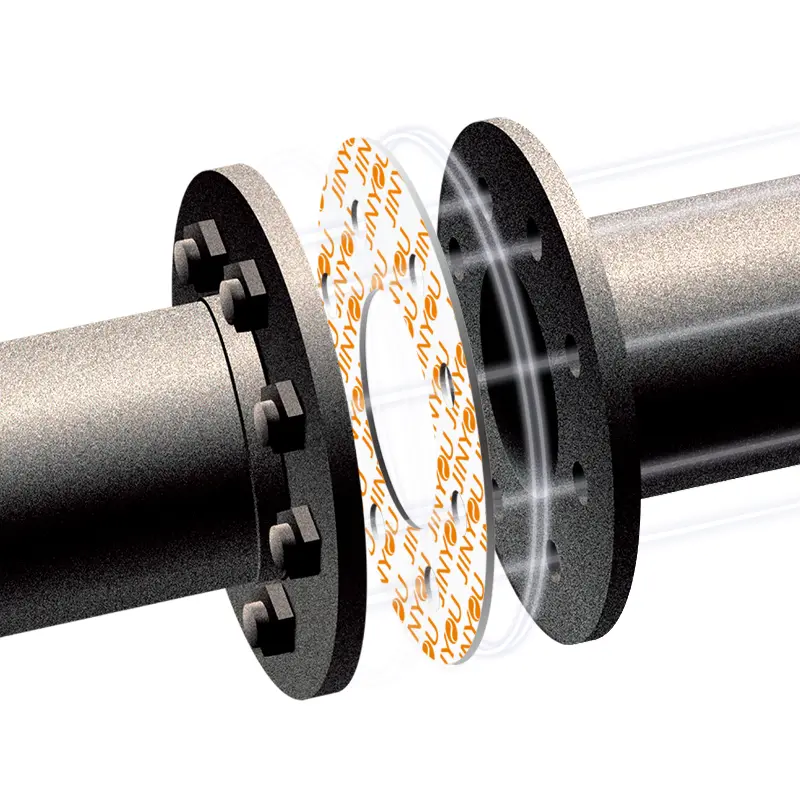

ePTFE tape, also known as expanded PTFE tape, is a versatile sealing material made from 100% PTFE that has been processed into a micro-porous, fibrous structure. It's commonly used as a form-in-place gasket material, especially in flange connections, due to its excellent sealing properties, chemical resistance, and ability to conform to uneven surfaces.

EPTFE tapes are Supplied/Manufactured in Two forms: Monoaxial and Multi-directional.

Mono axial ePTFE :

Mono axial ePTFE tapes, often used as joint sealants, are a type of expanded PTFE (ePTFE) tape that expands primarily in one direction (laterally) when compressed. This expansion characteristic, typically 200-300% of the original width, makes them highly conformable and easy to install on various flange types, including those with complex geometries. They are well-suited for applications where ease of installation and adaptability are crucial.

Key Characteristics and Applications:

-

Monoaxial Expansion:

The tape expands mainly in width when compressed, requiring careful consideration during installation to ensure proper fit.

-

Conformability:

Their flexibility allows them to easily adapt to uneven surfaces and complex flange geometries.

-

Ease of Installation:

Monoaxial ePTFE tapes are generally easy to install, often with a self-adhesive backing.

-

Wide Temperature and Chemical Resistance:

They are suitable for a wide range of static applications in various industries due to their thermal and chemical resistance.

-

Typical Applications:

Common uses include sealing flanges, pump housings, compressors, heat exchangers, and more.

Key Properties and Characteristics:

-

Form-in-place gasket:

ePTFE tape is designed to be easily installed on-site, conforming to the shape of the sealing surface.

-

Chemical resistance:

It is highly resistant to a wide range of chemicals, making it suitable for various industrial applications.

-

Temperature resistance:

ePTFE tapes can withstand a wide range of temperatures, from cryogenic to high temperatures, depending on the specific product.

-

Flexibility and conformability:

The expanded PTFE structure provides flexibility and compressibility, allowing it to seal even on uneven or damaged surfaces.

-

Adhesive backing:

Many ePTFE tapes come with a self-adhesive backing, simplifying installation and ensuring proper placement.

-

Longevity:

ePTFE is a durable material that does not age and has excellent UV resistance, offering long-term sealing performance.

Common Applications:

-

Flanged pipe connections:

ePTFE tapes are widely used to seal flanges in various industries, including chemical processing, oil and gas, and power generation.

-

Man-way hatches and reactor lids:

The tape's ability to conform to irregular surfaces makes it ideal for sealing these types of openings.

-

Aerospace industry:

ePTFE tapes are used in aerospace applications due to their lightweight nature and ability to withstand demanding conditions.

Multi-directional:

Traditional PTFE tapes often have a grain or fiber direction, meaning they are stronger

and more flexible in one

direction than another.

Multi-directional ePTFE tapes are engineered to have a more uniform fiber structure,

providing strength and flexibility

in both the longitudinal and cross directions.

This is achieved through specialized

manufacturing processes that create a more isotropic material.

Key Properties and Benefits:

-

Conformability :

The multi-directional structure allows the tape to easily conform to uneven or damaged sealing surfaces.

-

Creep Resistance:

Improved resistance to creep (deformation under load) compared to some other PTFE materials.

-

Low Stress Sealing:

Effective sealing at low bolt loads, which is important for sensitive or fragile applications.

-

Chemical Resistance:

Excellent resistance to a wide range of chemicals, making it suitable for various industries.

-

Temperature and Pressure Range:

Can handle a wide range of temperatures and pressures, depending on the specific product.

-

FDA Compliance:

Some multi-directional ePTFE tapes are FDA compliant, making them suitable for use in food and pharmaceutical applications.

-

Easy Installation:

Often self-adhesive on one side for easy application.

Common Applications:

-

Flange Gaskets:

Used on metallic, glass-lined, and other types of flanges in pipelines and apparatus.

-

Heat Exchangers:

Suitable for sealing heat exchanger flanges and other components.

-

Pressure Vessels:

Used in pressure vessels where a reliable seal is critical.

-

Irregular Surfaces:

Ideal for sealing areas with surface irregularities or damage.

-

Stress-Sensitive Joints:

Effective in applications where low bolt loads are required.

-

Manhole and Inspection Hole Connections:

Certain tapes are designed specifically for these applications.

Get in Touch

You will find yourself working in a true partnership that results in an incredible experience.

Call us on

+971 50 673 6705

Email us

cs@rudra-ventures.com